Performance

SAFF® Performance at a glance:

Traditional remediation technologies can be challenged by waters that present with high organics, co-contaminants or complex cross chemistries, but SAFF® has been purpose designed to effectively manage all types of challenging source waters and has proven its ability at a variety of complex sites around the world.

SAFF® relies on the surface-active nature of many PFAS compounds to allow it to be separated and removed. Depending on the types of compounds that local regulators require to be removed, and the particular PFAS signature encountered at a site, then SAFF® can either operate as a standalone technology or we may combine it with proprietary additives or even complimentary technologies.

The right configuration at your site can be assessed using the following table:

CRITERIA

SAFF® with post SAFF polishing

Physical characteristics of influent water

High organics

High TSS and TDS

Complex cross chemistries

High conductivity

eg PFDA, PFNA, PFOA, PFOS, PFHxS, 6:2FTS

e.g. PFHxA, PFPeA, PFBS

eg PFBA

Three steps to prove if SAFF® will perform effectively at your site:

SAFF® Predictability Model

SAFF® Bench Scale Testing

SAFF® Full Scale Testing

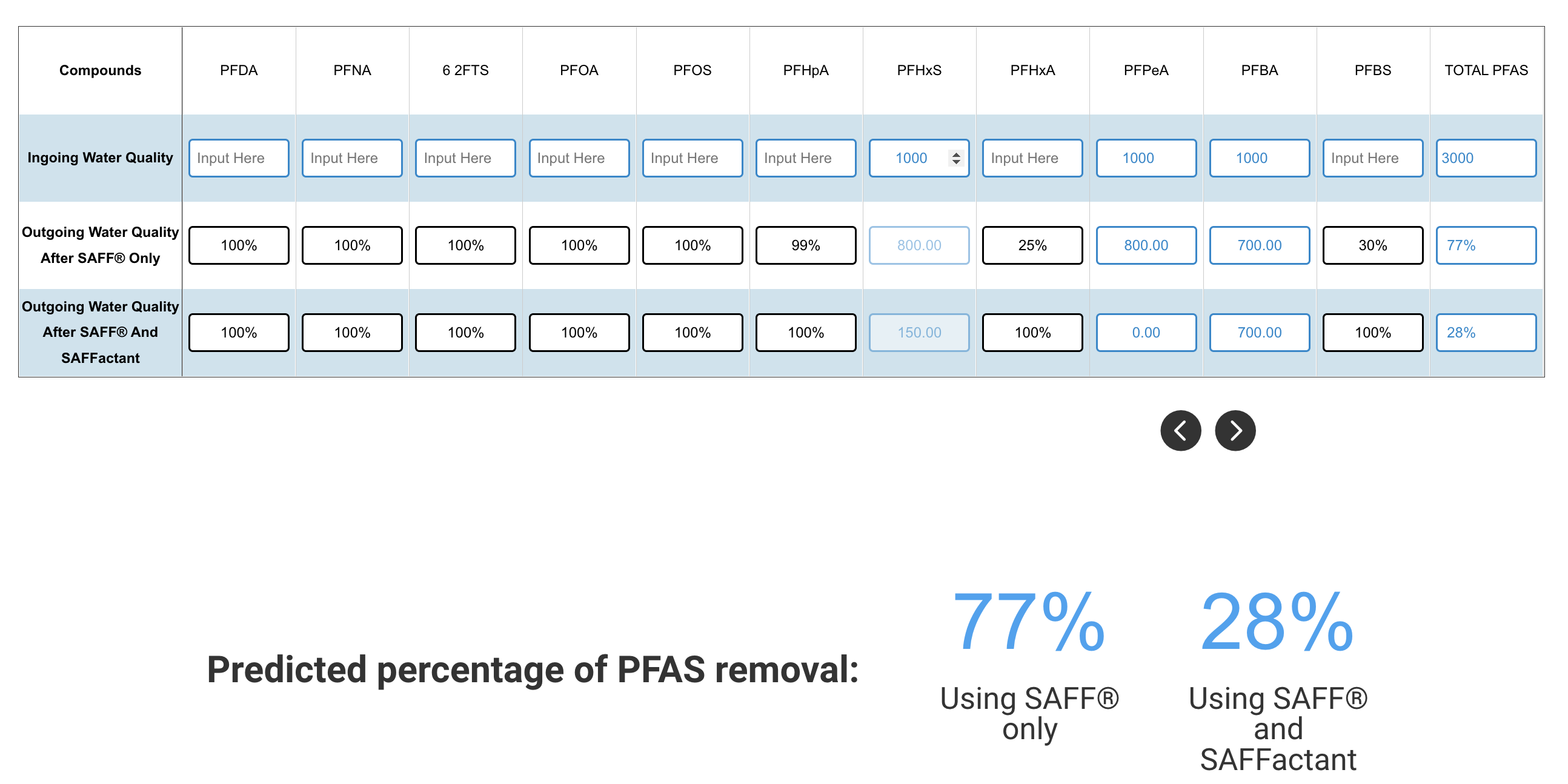

SAFF® predictability model

Plug in your water quality results to see how SAFF® can perform at your site

SAFF® systems located around the world have now treated many kinds of PFAS impacted waters including groundwaters, landfill leachates, wastewaters and process waters. This extensive data set has allowed us to develop an accurate predictability model, enabling clients to quickly understand how SAFF® is likely to perform at their site.

SAFF® can be operated as a standalone system utilising only air bubbles to remove a wide array of PFAS compounds, or it can be integrated with a dosing system using our proprietary additives which further improve the high level of performance by SAFF® in removing PFAS.

By inputting your sites water quality It will show (typically +/- 5%) how SAFF® is likely to perform at your site.

Compounds

Predicted Removal % Using SAFF Only

Predicted Removal % using SAFF® with SAFF additive

Outgoing Water Quality after SAFF® only

Outgoing Water Quality after SAFF® with SAFFactant additive

PFDA

100%

100%

PFNA

100%

100%

6 2FTS

100%

100%

PFOA

PFOA

100%

100%

100%

100%

PFHpA

PFHpA

80%

100%

99%

100%

PFHxA

PFHxA

20%

100%

25%

85%

PFBA

30%

30%

PFBS

30%

100%

SAFF® BENCHSCALE TESTING

Once you have established if SAFF® is suitable for your sites unique PFAS signature, EPOC can conduct accurate benchtop testing to prove the predictability model. A 25 gallon (100 litre) sample of the PFAS impacted site water is required to conduct these tests. EPOC will use this to conduct both primary and secondary fractionation experiments to test and demonstrate SAFF® performance.

As the Case Studies demonstrate, the results of the bench scale tests show a very high level of correlation with full scale field results and provide our clients with confidence and surety that their investment in a full scale SAFF® system will yield accurate, predictable results.

SAFF® FULL SCALE FIELD TRIAL

With the confidence of predictive modelling and bench scale results in hand, the client can then either move to full scale implementation or conduct a full-scale field trial.

Full scale field trials involve deployment of a SAFF20 system to the client’s site to conduct performance testing on the clients PFAS impacted waters. The SAFF20 system can process up to 20m3/hr of contaminated waters and categorically establish the performance capabilities of the SAFF® system at scale.

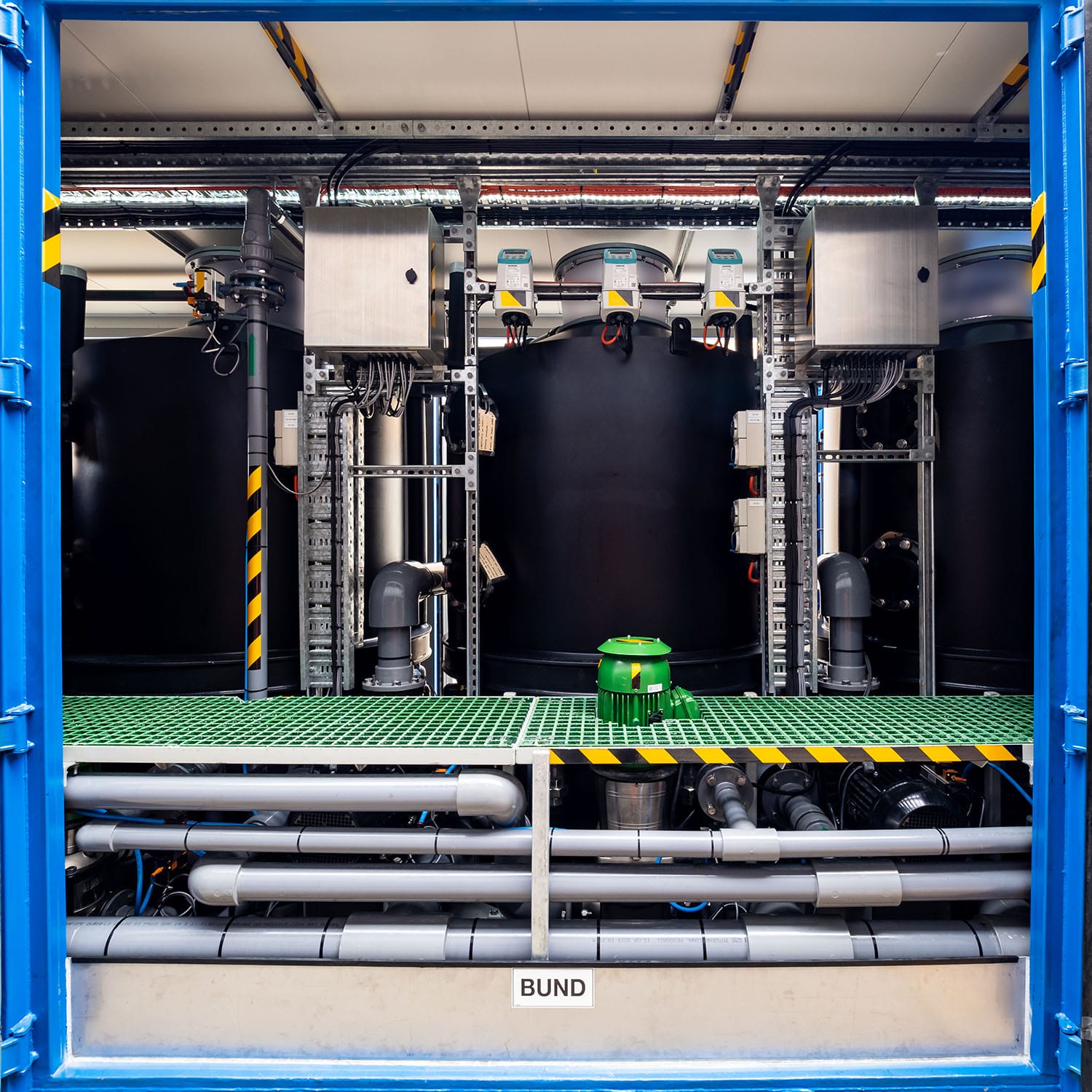

SAFF20

SAFF20 offers a convenient containerised PFAS water treatment plant that suits many lower flow sites. Housed in a 40’ shipping container, the system is the perfect choice for smaller water treatment projects with short to medium term timeframes.

The SAFF20 unit includes an enclosed weatherproof field office for staff to prepare samples and document the day’s activities, along with a control room and equipment storage area.

The SAFF20 is a low maintenance, plug and play system that can be operating within minutes of arriving on site. Its intuitive remote telemetry system means that it requires minimal on-site operator supervision.

- Capable of treating up to 20m3/hr.

- Configured with two primary SAFF vessels and one secondary SAFF vessel.

- Conveniently housed in an easily transportable 40’ shipping container (12.2 x 2.4m footprint).

- Lowest OPEX of any PFAS remediation technology.

- No consumables, such as IX Resin or GAC, are required.

- No solid waste produced. Concentrated PFAS is the only by-product of the process.

- Easily manages cross contamination, high organic and sediment loads, with no reduction in efficiency.

- Includes integrated site office, control room and spare parts storage area.

- Plug and play, self-bunded system which can be operating within minutes of arrival to site.

- Delivered to site using standard container handling vehicles, cranes or forklifts.

- High grade remote telemetry system means minimal operator presence on site.

SAFF40

SAFF40 is the compact workhorse in the SAFF fleet. The containerised solution provides high flow-through capabilities within a portable footprint. The SAFF40 suits the majority of PFAS impacted sites including landfills and source zone contamination areas.

- Capable of treating up to 40m3/hr.

- Configured with four primary SAFF vessels and two secondary SAFF vessels.

- Conveniently housed in an easily transportable 40’ shipping container (12.2 x 2.4m footprint).

- OPEX is many times lower than conventional treatment technologies.

- No consumables required (no IX Resin or GAC).

- No solid waste produced. Highly concentrated PFAS is the only by-product of the process.

- Can manage all contaminated water types from drinking water through to landfill leachates and sewerage.

- Covered workstation for sample preparation and paperwork.

- Highest throughput, lowest treatment cost containerised system available.

- Plug and play, self-bunded system can be operating within minutes of arrival to site.

- Delivered to site using standard container handling vehicles, cranes or forklifts.

- High grade remote telemetry system means minimal operator presence on site.

Do you have further questions about SAFF® performance? Take a look at our FAQs for more information

Fill in your details in the form below and you will be able to input your data to predict the percentage of PFAS removal for your water chemistry

Compounds

(ng/l / ppt)

Ingoing water quality

Outgoing water quality after SAFF® only

Outgoing water quality after SAFF® + SCRP

PFDA

PFNA

6:2FTS

PFOA

PFOS

PFHpA

PFHxS

PFHxA

PFPeA

PFBA

PFBS

TOTAL PFAS

Predicted percentage of PFAS removal:

-

Using SAFF® only

-

Using SAFF® + SCRP

EPOC Enviro’s predictability model historically provides accurate results but we cannot guarantee the results. For greater accuracy please ask us about our Bench Scale testing