PFAS Treatment by EPOC Enviro

Do you need a cost effective, efficient and sustainably engineered PFAS remediation technology?

SAFF ® is a proven and award winning solution, using a natural process to permanently reduce waste and ensure zero harm to the environment.

From landfill sites, airports, and military bases to sewerage treatment plants, water treatment plants, and industrial complexes, SAFF® is an optimal technology for your PFAS remediation needs.

SAFF® – THE BASICS

Surface Active Foam Fractionation, or SAFF® , is a sustainable remediation treatment that uses the power of rising air bubbles to rapidly remove harmful target PFAS contaminants from the environment.

If you are looking for a clean, proven and robust PFAS remediation solution, consider the many benefits of SAFF® .

SAFF® – Effective and Versatile

What is foam fractionation?

PFAS molecules are slippery critters. They migrate through soil and water with relative ease, while at other times they hang around layer upon layer on surfaces for way longer than we’d like them to.

SAFF® is a foam fractionation technology. Foam fractionation uses rising columns of bubbles to separate these molecules from a liquid solution. The bubbles form a foam or froth layer at the top of the column, which is then harvest from the solution and concentrated ready for destruction.

EPOC Enviro has refined foam fractionation to enable physical separation of PFAS from water using nothing more than aeration and clever design.

We put air in – we pull PFAS out.

The SAFF® Difference

Proven

SAFF® is proven over many years on multiple sites to rapidly remove PFAS compounds from water.

Cost effective

SAFF® comes with low and predictable CAPEX and OPEX costs and offers the lowest cost per treated liter.

Sustainable engineering

SAFF® contributes zero harm to the environment by using no consumables, minimal energy and labor, and produces no waste other than PFAS hyper-concentrate.

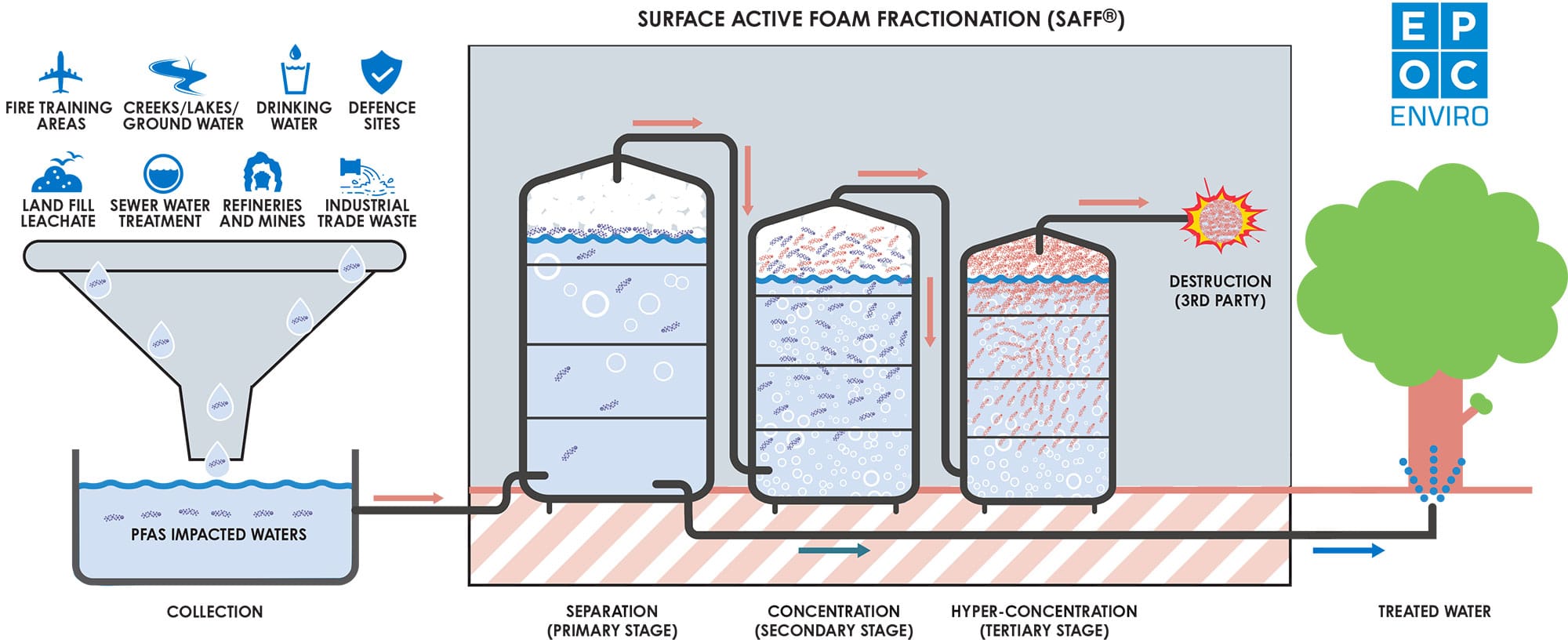

Separation, Concentration and Destruction of PFAS

Separation

Foam fractionation is used to separate the PFAS molecules from water.

Concentration

Foam fractionation continues to de-water the PFAS molecules and creates a PFAS rich hyper-concentrate, achieving concentration rates of up to 3.5 million times.

Destruction

Onsite destruction is achieved by pairing with third-party destruction technologies, such as electrochemical oxidation, super-critical water oxidation, reductive defluorination or cold plasma.

Key applications

Water – SAFF®

EPOC invented the SAFF® process for PFAS removal and hyper-concentration from all types of impacted waters. It effectively strips surface active PFAS compounds down to extremely low levels. SAFF® is an energy efficient, low cost, high-capacity process for treating PFAS impacted waters.

Soil – PFAST

The PFAST (PFAS Fractionation Assisted Soil Treatment) process was developed to treat and clean impacted soils and hardstand at highly contaminated sites. The process is a sustainable, high-volume technique applicable to a wide range of soil types. It can process up to 50 tonnes per day of PFAS impacted soil and can treat and recover 90-99 per cent of contaminated soils for beneficial on-site re-use.

Infrastructure – PFAIT

The PFAIT (PFAS Fractionation Assisted Infrastructure Treatment) system uses powerful PFAS scrubbing chemistries combined with foam fractionation to strip residual PFAS compounds bound to valuable infrastructure, like fire-fighting appliances, storage tanks, and sprinkler systems. You can ensure the cost effective recovery and reutilisation of PFAS impacted assets which would otherwise need to be removed and replaced.