Service And Support

With your SAFF® unit installed and successfully operating on site, it is important to understand that EPOC’s service and support does not stop there. We expect that the SAFF® systems will operate in even the harshest of industrial treatment environments for ten to twenty years, so a comprehensive after sales and support capability is imperative to the long-term viability of the SAFF® system.

Our after sales, service and support capabilities are divided into six key areas:

Scheduled Maintenance

Due to the simple and elegant design of the SAFF® systems, the required level of maintenance expected on the SAFF® units is quite low.

On average, 4-8 hours a month of scheduled maintenance work is recommended to ensure that the system remains in optimal operating condition.

EPOC technicians and their qualified territory agents can be engaged to provide regular checks and inspections of the plant to ensure many years of successful operation.

Reactive Maintenance

In the event that a failure occurs for any reason in the system, EPOC technicians are on call to undertake emergency maintenance and repairs and to bring the system back online with minimal delays.

EPOC’s strategically located maintenance depots stock all necessary parts and materials to ensure timely delivery, resulting in minimal downtime and maximum productivity.

Remote telemetry

Every component within the SAFF® system which operates via an electrical impulse sends a signal to EPOC’s remote telemetry platform. Additionally, each SAFF® is fitted with remote access video cameras. Using the onboard wireless communications system, these signals are directed to the EPOC central control facility. With the insight that these technologies provide, 99 out of 100 faults encountered within the SAFF® system can be resolved remotely, inexpensively and expediently.

Where time is of the essence, EPOC’s remote telemetry service is a cost-effective strategy for ensuring around-the-clock oversight of your PFAS treatment system.

Where problems cannot be resolved remotely, EPOC’s control facility technicians will immediately notify clients and appropriate sub-contractors of any issues and arrange for timely repairs and maintenance works to be carried out with minimal delay.

Tertiary Waste Concentration

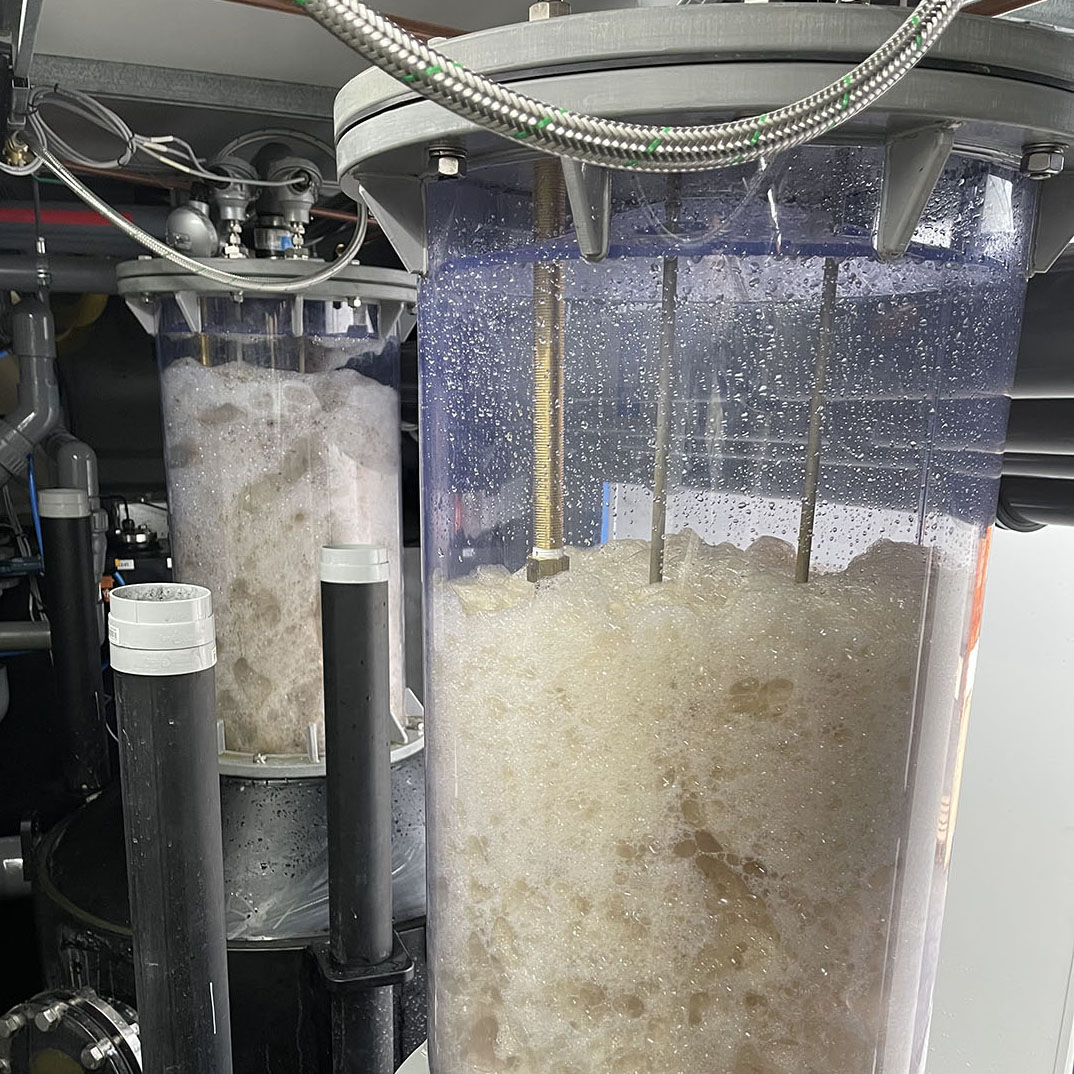

The EPOC SAFF® system automatically produces a concentrate, referred to as the secondary fractionate, which dramatically reduces the volume of PFAS impacted waste requiring disposal.

To enhance the SAFF® system performance, EPOC also offers an optional manual tertiary fractionation service.

With ample notice, EPOC technicians will be remotely notified that the secondary fractionation tank requires treatment and will come to site with a trailer based tertiary fractionator.

This enables further de-watering and minimization of the waste stream and creates a PFAS hyper-concentrate ready for disposal.

Depending on the influent water quality, the SAFF® tertiary fractionation process can achieve concentration factors of between 30,000 and 3 million times, resulting in miniscule volumes of PFAS waste.

Unlike other treatment technologies, this SAFF tertiary technique ensures that no PFAS impacted solid waste, such as spent GAC or IX resins, goes to landfill, permanently removing the PFAS from the environment.

Tertiary Waste Destruction

Once the SAFF® tertiary waste has been produced, it is ready for disposal. Whilst traditional techniques can be used, such as high temperature off-site destruction, or solidification and landfilling, EPOC offers a unique on-site destruction alternative through its third-party partners.

The tiny volumes of tertiary PFAS hyper-concentrate can be completely and effectively destroyed on-site utilising portable destruction technologies which accompany the tertiary fractionation trailer.

By permanently removing PFAS from the environment, EPOC’s on-site destruction service closes the loop in the PFAS contamination cycle. This offers not only a sustainable, but also an economical PFAS destruction pathway.

Supportive Chemistry

Where regulators require high levels of short chain (C4 – C5) removal, EPOC has developed a proprietary surfactant. This unique additive maximizes PFAS short chain uptake without adding any additional problematic chemistries to the water stream.

This ability to combine the power of rising air bubbles with an environmentally responsible PFAS extraction chemistry ensures that even the most stringent of PFAS management frameworks can be met and exceeded.

The importance of this unique marriage cannot be understated as it allows SAFF® to not only meet the performance capabilities of all other remediation techniques, but it does so using only air bubbles; no consumable adsorbents like resin or GAC and no off-site waste. It artfully achieves this sustainable outcome at only a fraction of the cost of other remediation techniques.

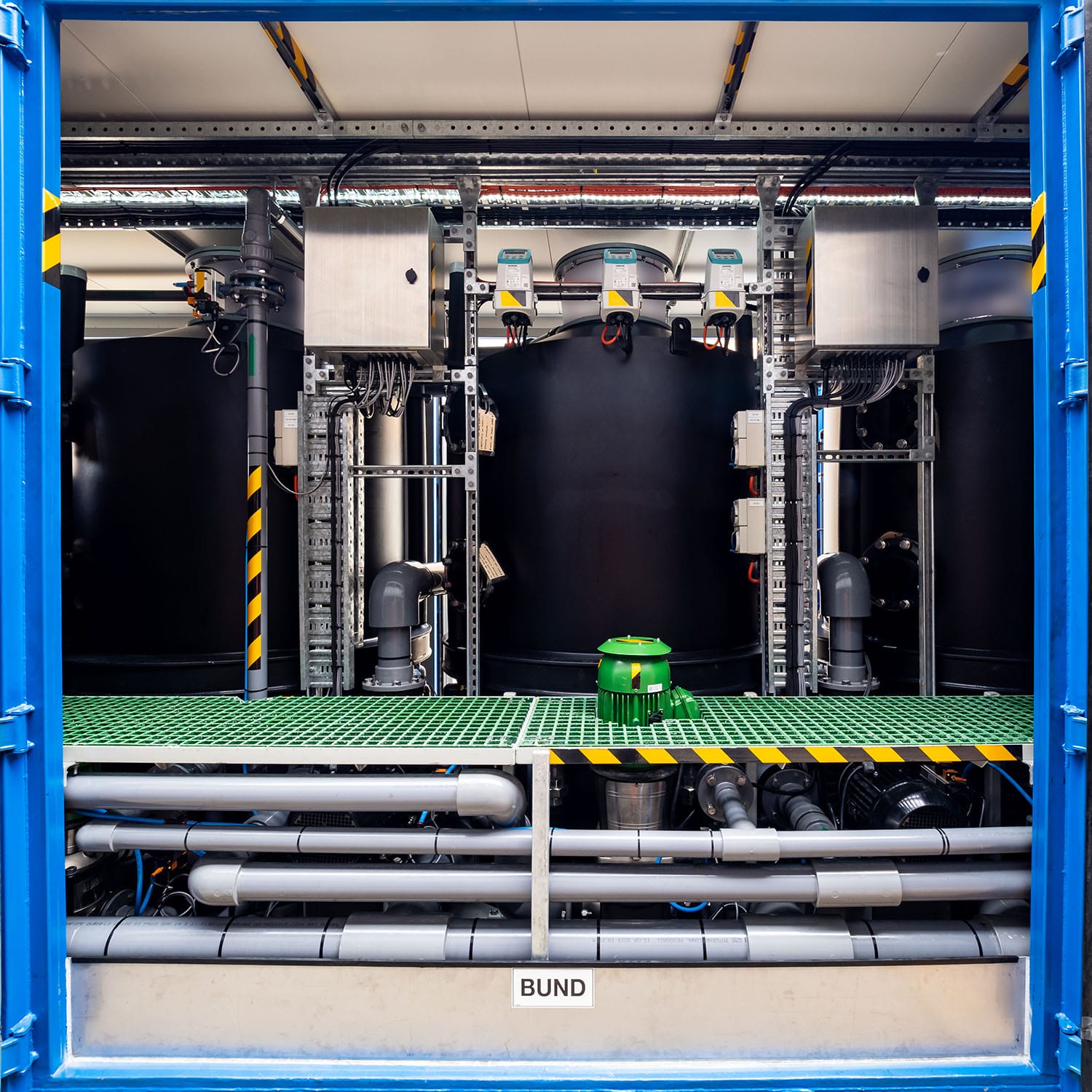

SAFF20

SAFF20 offers a convenient containerised PFAS water treatment plant that suits many lower flow sites. Housed in a 40’ shipping container, the system is the perfect choice for smaller water treatment projects with short to medium term timeframes.

The SAFF20 unit includes an enclosed weatherproof field office for staff to prepare samples and document the day’s activities, along with a control room and equipment storage area.

The SAFF20 is a low maintenance, plug and play system that can be operating within minutes of arriving on site. Its intuitive remote telemetry system means that it requires minimal on-site operator supervision.

- Capable of treating up to 20m3/hr.

- Configured with two primary SAFF vessels and one secondary SAFF vessel.

- Conveniently housed in an easily transportable 40’ shipping container (12.2 x 2.4m footprint).

- Lowest OPEX of any PFAS remediation technology.

- No consumables, such as IX Resin or GAC, are required.

- No solid waste produced. Concentrated PFAS is the only by-product of the process.

- Easily manages cross contamination, high organic and sediment loads, with no reduction in efficiency.

- Includes integrated site office, control room and spare parts storage area.

- Plug and play, self-bunded system which can be operating within minutes of arrival to site.

- Delivered to site using standard container handling vehicles, cranes or forklifts.

- High grade remote telemetry system means minimal operator presence on site.

SAFF40

SAFF40 is the compact workhorse in the SAFF fleet. The containerised solution provides high flow-through capabilities within a portable footprint. The SAFF40 suits the majority of PFAS impacted sites including landfills and source zone contamination areas.

- Capable of treating up to 40m3/hr.

- Configured with four primary SAFF vessels and two secondary SAFF vessels.

- Conveniently housed in an easily transportable 40’ shipping container (12.2 x 2.4m footprint).

- OPEX is many times lower than conventional treatment technologies.

- No consumables required (no IX Resin or GAC).

- No solid waste produced. Highly concentrated PFAS is the only by-product of the process.

- Can manage all contaminated water types from drinking water through to landfill leachates and sewerage.

- Covered workstation for sample preparation and paperwork.

- Highest throughput, lowest treatment cost containerised system available.

- Plug and play, self-bunded system can be operating within minutes of arrival to site.

- Delivered to site using standard container handling vehicles, cranes or forklifts.

- High grade remote telemetry system means minimal operator presence on site.

For more information on our SAFF® systems and how they work, take a look at our products page.