Frequently Asked Questions

SAFF20

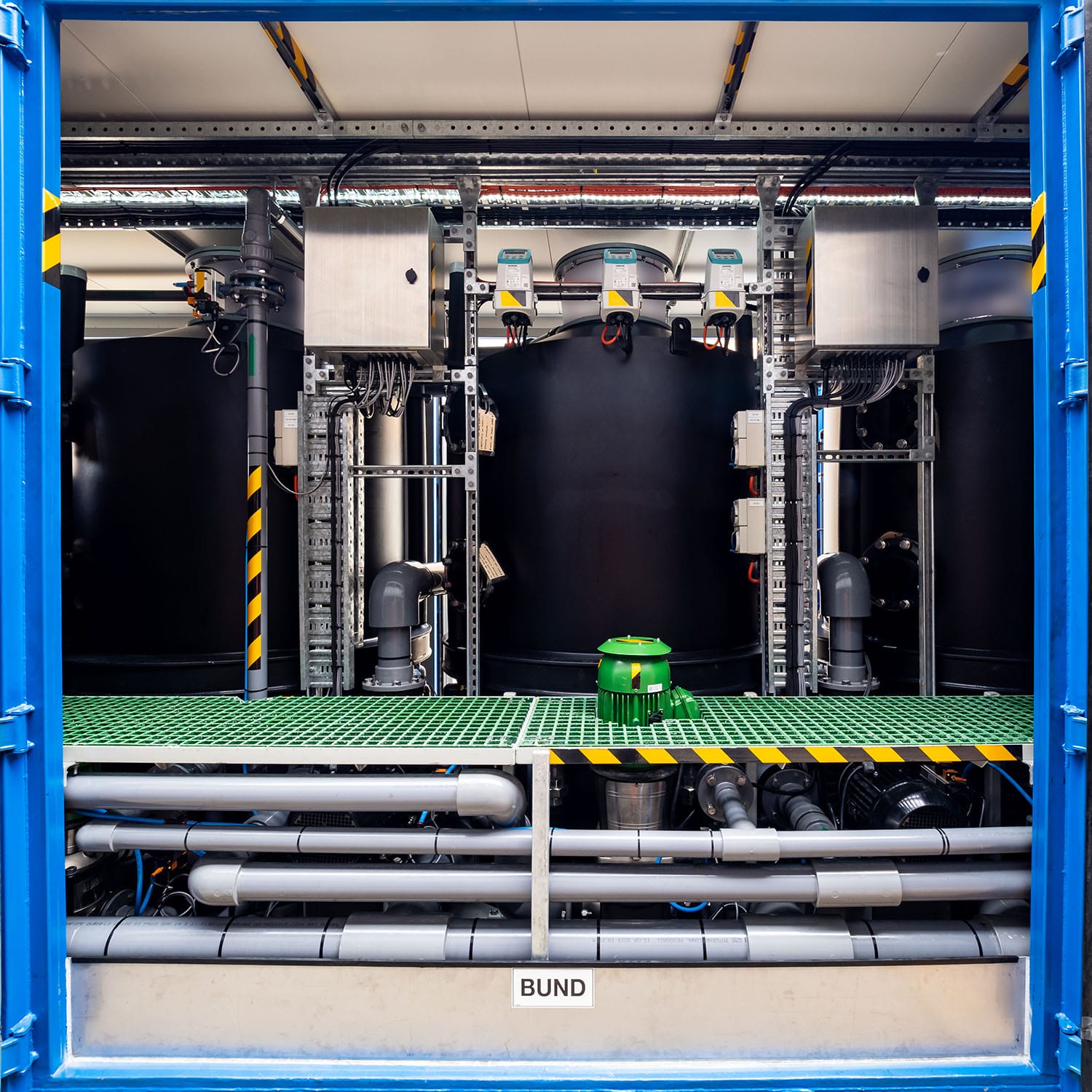

SAFF20 offers a convenient containerised PFAS water treatment plant that suits many lower flow sites. Housed in a 40’ shipping container, the system is the perfect choice for smaller water treatment projects with short to medium term timeframes.

The SAFF20 unit includes an enclosed weatherproof field office for staff to prepare samples and document the day’s activities, along with a control room and equipment storage area.

The SAFF20 is a low maintenance, plug and play system that can be operating within minutes of arriving on site. Its intuitive remote telemetry system means that it requires minimal on-site operator supervision.

- Capable of treating up to 20m3/hr.

- Configured with two primary SAFF vessels and one secondary SAFF vessel.

- Conveniently housed in an easily transportable 40’ shipping container (12.2 x 2.4m footprint).

- Lowest OPEX of any PFAS remediation technology.

- No consumables, such as IX Resin or GAC, are required.

- No solid waste produced. Concentrated PFAS is the only by-product of the process.

- Easily manages cross contamination, high organic and sediment loads, with no reduction in efficiency.

- Includes integrated site office, control room and spare parts storage area.

- Plug and play, self-bunded system which can be operating within minutes of arrival to site.

- Delivered to site using standard container handling vehicles, cranes or forklifts.

- High grade remote telemetry system means minimal operator presence on site.

SAFF40

SAFF40 is the compact workhorse in the SAFF fleet. The containerised solution provides high flow-through capabilities within a portable footprint. The SAFF40 suits the majority of PFAS impacted sites including landfills and source zone contamination areas.

- Capable of treating up to 40m3/hr.

- Configured with four primary SAFF vessels and two secondary SAFF vessels.

- Conveniently housed in an easily transportable 40’ shipping container (12.2 x 2.4m footprint).

- OPEX is many times lower than conventional treatment technologies.

- No consumables required (no IX Resin or GAC).

- No solid waste produced. Highly concentrated PFAS is the only by-product of the process.

- Can manage all contaminated water types from drinking water through to landfill leachates and sewerage.

- Covered workstation for sample preparation and paperwork.

- Highest throughput, lowest treatment cost containerised system available.

- Plug and play, self-bunded system can be operating within minutes of arrival to site.

- Delivered to site using standard container handling vehicles, cranes or forklifts.

- High grade remote telemetry system means minimal operator presence on site.

FAQs

What is PFAS?

- Per- and polyfluoroalkyl substances (PFAS) is a group of man-made chemicals that include PFOA, PFOS, PFHxS, and many thousands of other synthetic chemicals.

- PFAS has used worldwide since the 1950’s to make products that resist heat, stains, oil/grease and water.

- Until around 2004, PFAS compounds were present in aqueous film forming foam (AFFF) which is a firefighting foam used worldwide to extinguish fires.

- PFAS chemicals are also used in non-stick cookware; fabric, furniture and carpet stain protection applications; food packaging and many industrial processes.

- PFAS compounds are generally very stable. They do not break down in the environment and they can accumulate over time.

- Over decades, PFAS chemicals leach through soil to reach the groundwater beneath.

- There is evidence that exposure to PFAS can lead to adverse human health effects.

Where is PFAS Located?

- PFAS contamination has become global. Typical source locations include defence bases, airports, industrial trade waste, refineries, mines, sewer water treatment and landfill leachate. It can also be found within drinking water and in creeks, lakes, wells and other groundwater sources.

- The Centers for Disease Control and Prevention (CDC) found PFOA in the blood of 98 per cent of Americans.

- Effective remediation from water is an essential first step in removing this harmful contaminant from the environment.

How does SAFF compare to other PFAS remediation technologies?

- SAFF has the lowest OPEX cost on the market

- SAFF clients do not have to deal with the secondary waste of exhausted media requiring disposal

- SAFF delivers consistently low treatment costs regardless of PFAS concentrate levels

- SAFF is untroubled by co-contaminants

- SAFF helps to satisfy client targets for sustainability and environmental responsibility

Why is SAFF technology a game changer for PFAS remediators?

- SAFF is a versatile and robust remediation technology that has proven its ability to work in waters with high percentages of co-contaminants.

- It is also the most sustainable technology on the market, and simply uses the power of air to foam out PFAS contaminants from solution. In fact, the only waste product produced by SAFF is PFAS hyper-concentrate.

- SAFF is most effective in its removal of PFAS ≥C6 chemistry and is achieving independently validated results of results of 100 per cent for PFOS/PFOA and 99 per cent for PFHxS.

- A PFAS super concentrate means less waste removal.

- A continuous water treatment, SAFF has been neatly containerised for portability and plug and play application.

Why are PFAS contaminants harmful?

- PFAS chemicals are known as an ‘emerging contaminant’, and their specific impact on the environment and humans is still being reviewed.

- PFOS was listed on the Stockholm Convention (Annexure B – POP’s for restriction, May 2009),

- PFOA was listed on the Stockholm Convention (Annexure A – POP’s for elimination, May 2019)

- PFHxS is proposed for listing/review on the Stockholm Convention.

- Concerns relate to their characteristics of persistence, bio-accumulation and toxicity.

What is PFOS and how does it relate to PFAS?

- PFOS is an acronym for Perfluoro-octane sulphonate, which is regarded as a legacy PFAS compound containing eight carbon atoms in the carbon backbone.

- PFOS is a stable end-point compound which means under normal environmental conditions the molecule does not break down (persistent), concentrates in media including human and environmental media (bio-accumulates), preliminary toxicology research is concerned about potential health effects (potential for toxicity), and migrates at various rates in various environmental media (mobility).

What other PFAS compounds have international criteria?

- The following priority PFAS chemicals/compounds are scrutinised by environmental managers and contractors who provide remediation solutions to remove them from environmental waters, soils, and some hardstand materials: PFOS, PFHxS, PFOA, FOSA (PFOSA), PFNA, PFDA, 6:2-FTS, 8:2-FTS, PFHpA, PFHxA, PFPeA, PFBS, PFBA and GenX.

What is foam fractionation?

- Foam fraction is a physical separation and concentration process which EPOC Enviro has reinvented to remove PFAS and other high Henry’s constant co-contaminants from water in a single step.

- Foam fractionation takes advantage of the partitioning process of PFAS molecules at the thin surface layer interface between water and gas – in this case air.

- It removes bulk detectable PFAS > 85% including 99% priority long chains (PFOS, PFHxS, PFOA and precursors) within minutes to low levels.

- The process produces an extremely low volume/high concentration foam waste.

- SAFF uses a real-time vacuum to make this process rapid which provides a commercial advantage when used in a treatment train.

Is EPOC Enviro collaborating with research institutions?

Yes, in Australia at Macquarie University and University NSW (ADFA Campus ACT).

Internationally, EPOC Enviro (trading outside the USA as OPEC Systems) is collaborating with the:

- EU – Scenarios project

- EU – Horizons project

Why is the concentration step so important in your PFAS remediation treatment offering?

Concentration is important as it reduces the overall volume of PFAS waste, making destruction easier and more economical. SAFF® can achieve concentration factors of 3.5M times. For every Olympic sized pool of water that SAFF® treats, it generates around a coffee cup of PFAS hyper-concentrate.

How does SAFF® compare to PFAS remediation technologies that use adsorbents such as GAC and resin?

Both technologies work effectively at stripping PFAS from water, but only SAFF® generates zero waste (other than PFAS), meaning that clients can achieve environmental benchmarks and do not have to deal with the disposal of secondary waste

My site has high PFAS contamination levels. Does this mean I require a more extensive treatment?

No, it doesn’t. Regardless of the PFAS concentration levels, SAFF® performs efficiently and effectively, with consistently low treatment costs.

My site has a complex mix of other chemistries in the PFAS impacted waters. Will SAFF® still work?

Yes, it sure will. Because of the infinite capacity of the bubble surface to harvest PFAS compounds, it is not adversely affected by other chemistries or surface-active products being present in the treatment waters.

Does the SAFF® system require a lot of maintenance or the presence of a permanent operator?

No, the SAFF® contains some very clever remote telemetry capabilities which means that most problems can be dealt with from the control room of our 24/7 technical team.

Do you want to find out more about our SAFF® capabilities? Speak to our team today